Precision weed control

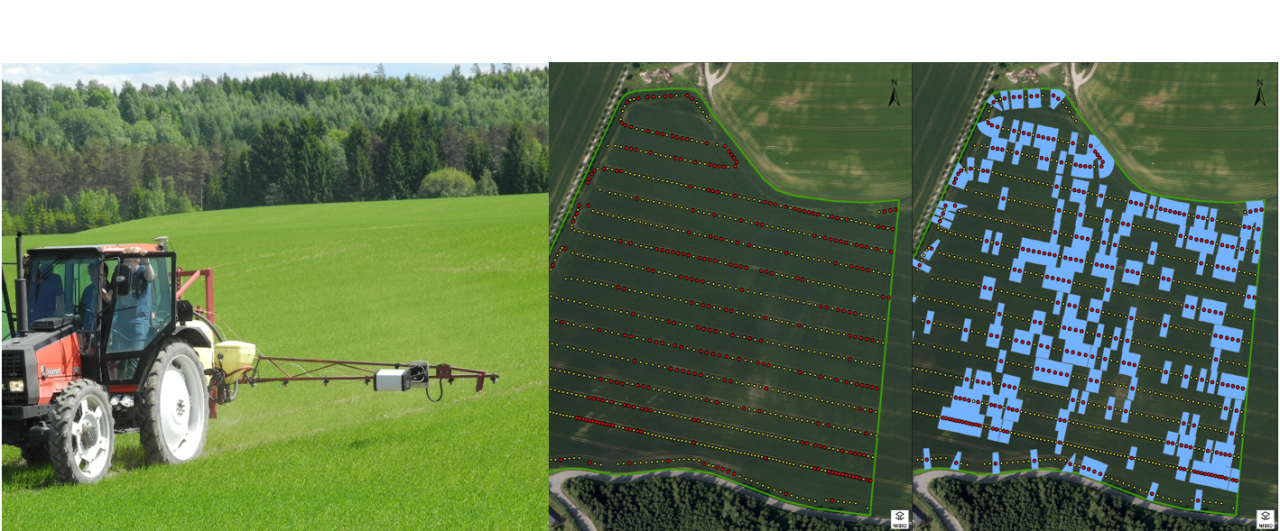

Weeds tend to occur in patches. Yet, weed control is usually conducted uniformly, potentially causing unnecessary use of herbicides or diesel. To avoid superfluous spraying and tillage operations, weeding measures should be adjusted to the actual weed distribution. Such site-specific weed management is possible if we combine sensor technology with agronomic knowledge into precision weed control.

Principally, precision weed control is nothing new. Traditional weeding by hand is a very a precise operation guided by two sensors and a decision model: our eyes and brain. Precision weed control in a modern context makes use of new technologies. Sensors - cameras and non-imaging sensors - , software giving meaning to the sensor readings and satellite-based positioning systems, are usually the minimum requirements. The new technologies can also include the weeding implement itself. Examples are direct injection sprayers, multi-tank sprayers, variable rate nozzles, robotic single drop spraying and new blades for root cutting.

Additionally, sound precision weeding requires valid decision models developed by experts. This is essential. Based on knowledge on the weeding tool, the weeds and crop in question, the decision model translates georeferenced sensor-based weed observations into valid site-specific weed control.

Reduced environmental impact of weed control in agriculture is the main motivation for precision weeding. - But perhaps costs to herbicides and diesel can be reduced as well? Furthermore, could fields under site-specific weed management benefit from increased diversity of weeds? - Could such fields perhaps be attractive for pest insects’ natural enemies?

Precision weed control can be seen as a topic within precision crop protection and precision agriculture. It can also be a tool in Integrated Pest Management, especially IPM principle No. 6.

Here you find links to some of our projects and publications on precision weed control. Our projects represent a rather wide range, from robotic application of single droplets of herbicides in seeded root vegetables to camera-based mapping of creeping thistle in cereals from the harvester.

Publications

Abstract

No abstract has been registered

Abstract

Weeds affect crop yield and quality due to competition for resources. In order to reduce the risk of yield losses due to weeds, herbicides or non-chemical measures are applied. Weeds, especially creeping perennial species, are generally distributed in patches within arable fields. Hence, instead of applying control measures uniformly, precision weeding or site-specific weed management (SSWM) is highly recommended. Unmanned aerial vehicle (UAV) imaging is known for wide area coverage and flexible operation frequency, making it a potential solution to generate weed maps at a reasonable cost. Efficient weed mapping algorithms need to be developed together with UAV imagery to facilitate SSWM. Different machine learning (ML) approaches have been developed for image-based weed mapping, either classical ML models or the more up-to-date deep learning (DL) models taking full advantage of parallel computation on a GPU (graphics processing unit). Attention-based transformer DL models, which have seen a recent boom, are expected to overtake classical convolutional neural network (CNN) DL models. This inspired us to develop a transformer DL model for segmenting weeds, cereal crops, and ‘other’ in low-resolution RGB UAV imagery (about 33 mm ground sampling distance, g.s.d.) captured after the cereal crop had turned yellow. Images were acquired during three years in 15 fields with three cereal species (Triticum aestivum, Hordeum vulgare, and Avena sativa) and various weed flora dominated by creeping perennials (mainly Cirsium arvense and Elymus repens). The performance of our transformer model, 1Dtransformer, was evaluated through comparison with a classical DL model, 1DCNN, and two classical ML methods, i.e., random forest (RF) and k-nearest neighbor (KNN). The transformer model showed the best performance with an overall accuracy of 98.694% on pixels set aside for validation. It also agreed best and relatively well with ground reference data on total weed coverage, R2 = 0.598. In this study, we showed the outstanding performance and robustness of a 1Dtransformer model for weed mapping based on UAV imagery for the first time. The model can be used to obtain weed maps in cereals fields known to be infested by perennial weeds. These maps can be used as basis for the generation of prescription maps for SSWM, either pre-harvest, post-harvest, or in the next crop, by applying herbicides or non-chemical measures.

Abstract

No abstract has been registered

Abstract

Weeds may reduce crop yields significantly if managed improperly. However, excessive herbicide use increases risk of unwanted effects on ecosystems, humans and herbicide resistance development. Weed harrowing is a traditional method to manage weeds mechanically in organic cereals but could also be used in conventional production. The weed control efficacy of weed harrowing can be adjusted by e.g. the angle of the tines. Due to its broadcast nature (both crop and weed plants are disturbed), weed harrowing may have relatively poor selectivity (i.e. small ratio between weed control and crop injury). To improve selectivity, a sensor-based model which takes into account the intra-field variation in weediness and “soil density” in the upper soil layer (draft force of tines), is proposed. The suggested model is a non-linear regression model with three parameters and was based on five field trials in spring barley in SE Norway. The model predicts the optimal weed harrowing intensity (in terms of the tine angle) from the estimated total weed cover and SD per sub-field management unit, as well as a pre-set biological weed threshold (defined as the acceptable total weed cover left untreated). Weed cover and SD were estimated with RGB images (analysed with custom-made machine vision) and an electronic load cell, respectively. With current parameter values, the model should be valid for precision weed harrowing in spring barley in SE Norway. The next step is to test the model, and if successful, adjust it to more cereal species. Weeds may reduce crop yields significantly if managed improperly. However, excessive herbicide use increases risk of unwanted effects on ecosystems, humans and herbicide resistance development. Weed harrowing is a traditional method to manage weeds mechanically in organic cereals but could also be used in conventional production. The weed control efficacy of weed harrowing can be adjusted by e.g. the angle of the tines. Due to its broadcast nature (both crop and weed plants are disturbed), weed harrowing may have relatively poor selectivity (i.e. small ratio between weed control and crop injury). To improve selectivity, a sensor-based model which takes into account the intra-field variation in weediness and “soil density” in the upper soil layer (draft force of tines), is proposed. The suggested model is a non-linear regression model with three parameters and was based on five field trials in spring barley in SE Norway. The model predicts the optimal weed harrowing intensity (in terms of the tine angle) from the estimated total weed cover and SD per sub-field management unit, as well as a pre-set biological weed threshold (defined as the acceptable total weed cover left untreated). Weed cover and SD were estimated with RGB images (analysed with custom-made machine vision) and an electronic load cell, respectively. With current parameter values, the model should be valid for precision weed harrowing in spring barley in SE Norway. The next step is to test the model, and if successful, adjust it to more cereal species.

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Ran Nisim Lati Jesper Rasmussen Dionisio Andújar Jose Dorado Therese With Berge Christina Wellhausen Michael Pflanz Henning Nordmeyer Michael Schirrmann Hanan Eizenberg Paul Neve Rasmus Nyholm Jørgensen Svend ChristensenAbstract

The adoption of site-specific weed management (SSWM) technologies by farmers is not aligned with the scientific achievements in this field. While scientists have demonstrated significant success in real-time weed identification, phenotyping and accurate weed mapping by using various sensors and platforms, the integration by farmers of SSWM and weed phenotyping tools into weed management protocols is limited. This gap was therefore a central topic of discussion at the most recent workshop of the SSWM Working Group arranged by the European Weed Research Society (EWRS). This insight paper aims to summarise the presentations and discussions of some of the workshop panels and to highlight different aspects of weed identification and spray application that were thought to hinder SSWM adoption. It also aims to share views and thoughts regarding steps that can be taken to facilitate future implementation of SSWM.

Abstract

No abstract has been registered

Abstract

No abstract has been registered

Abstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Trygve Utstumo Frode Urdal Anders Brevik Jarle Dørum Jan Netland Øyvind Overskeid Therese With Berge Jan Tommy GravdahlAbstract

© 2018. This is the authors’ accepted and refereed manuscript to the article. Locked until 7.9.2020 due to copyright restrictions. This manuscript version is made available under the CC-BY-NC-ND 4.0 license http://creativecommons.org/licenses/by-nc-nd/4.0/

Authors

Therese With BergeAbstract

No abstract has been registered

Abstract

Forprosjektet "Test av kommersiell teknologi for presisjonssprøyting av glyfosat i kornproduksjon" er finansiert av Forskningsmidlene for jordbruk og matindustri (tilsagnsnr. 119059)

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

2 siders handout ifm "Grøna møten: Framtidsspaning för hållbart lantbruk i Norden" arrangert av Agroväst Livsmedel AB (Skara)på Naturbruksskolan Uddetorp, Skara, Sverige, 6. desember 2018

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Ricardo Fonseca Werner Creixell Javier Maiguashca Victor Rueda-AyalaAbstract

Image analysis is essential through a wide range of scientific areas and most of them have one task in common, i.e. object detection. Thus automated detection algorithms had generated a lot of interest. This proposal identifies objects with similar features on a frame. The inputs are the image where to look at, and a single appearance of the object we are looking for. The object is searched by a sliding window of various sizes. A positive detection is given by a cascaded classifier that compares input patches from sliding window to the object model. The cascaded classifier has three stages: variance comparison, layers of pixel comparisons and patch correlation. Object model is a collection of templates which are generated from scales and rotations of the first appearance. This algorithm is capable to handle change in scale, in plane rotation, illumination, partial occlusion and background clutter. The proposed framework was tested on high cluttered background aerial image, for identifying palm oil trees. Promising results were achieved, suggesting this is a powerful tool for remote sensing image analysis and has potential applications for a wide range of sciences which require image analysis.

Abstract

No abstract has been registered

Abstract

With the Directive 2009/128/EC on sustainable use of pesticides, reductions in herbicide use is a European target. The aim of this study was to compare the fi eld-specifi c herbicide use resulting from simulated integrated weed management (IWM) with farmer’s actual use. Two IWM tools applicable for cereals were explored: VIPS – a web-based decision support system, and DAT sensor – a precision farming technology for patch spraying. VIPS (adaptation of Danish “Crop Protection Online”) optimizes herbicide – and dose to weed species densityand growth stage (including ALS-herbicide resistant populations), temperature, expected yield, cereal species- and growth stage. Weeds were surveyed (0.25 m2, n=23-31) prior to post-emergence spraying in spring 2013 (six fi elds) and 2014 (eight fi elds). DAT sensor enables automatic patch spraying of annual weeds within cereals. It consists of an RGB camera and custom-made image analysis. DAT sensor acquired more than 900 images (0.06 m2) per fi eld. Threshold for simulated patch spraying was relative weed cover (weed cover/ total vegetation cover) = 0.042. Treatment frequency index (TFI, actual dose/maximum approved dose summed for all herbicides) was calculated. Without resistance strategy, average TFI for VIPS was higher for winter wheat (0.96) than for spring cereals (0.38). Spring cereal fi elds with resistance strategies gave an average TFI of 1.45. Corresponding TFI for farmer’s applications were 1.40, 0.90 and 1.26, respectively. For one fi eld wherein both tools were explored in 2013 and 2014, TFI values for VIPS were 1.86 and 1.50 due to resistant Stellaria media, while TFI for farmer’s sprayings were around 1.00. DAT sensor simulated herbicide savings of 69% and 99%, corresponding to TFI values of 0.58 and 0.01, respectively. As measured by TFI, DAT sensor showed a higher potential in herbicide savings than VIPS. VIPS is available without costs to end-users today, while DAT sensor represents a future tool.

Abstract

No abstract has been registered

Authors

Audun KorsæthAbstract

No abstract has been registered

Authors

Trygve Utstumo Jarle Dørum Mathias Hauan Arbo Therese With Berge Steve Goldberg Øyvind Overskeid Jan Tommy GravdahlAbstract

Asterix-prosjektet utvikler en selvgående robot for automatisk ugraskontroll i radkulturer. Med et slikt system vil forbruket av ugrasmiddel bli svært lavt, i størrelsesorden 5-10% av vanlig praksis (breisprøyting). Presisjonsjordbruk er et konsept hvor innsatsmidler eller dyrkningstiltak tilpasses den romlige variasjonen i behov for f.eks. gjødsel, plantevernmidler, vann og mekanisk ugraskontroll innen en åker. Presisjonsjordbruk kan gi økt avling og bedre kvalitet da innsatsmidler og tiltak optimaliseres, samtidig reduseres miljøpåvirkningen ved at f.eks. unødig sprøyting unngås.

Authors

Therese With Berge Trygve Utstumo Jan NetlandAbstract

No abstract has been registered

Abstract

No abstract has been registered

Abstract

No abstract has been registered

Abstract

Vehicles which operate in agricultural row crops, need to strictly follow the established wheel tracks. Errors in navigation where the robot sways of its path with one or more wheels may damage the crop plants. The specific focus of this paper is on an agricultural robot operation in row cultures. The robot performs machine vision detecting weeds within the crop rows and treats the weeds by high precision drop-on-demand application of herbicide. The navigation controller of the robot needs to follow the established wheel tracks and minimize the camera system offset from the seed row. The problem has been formulated as a Nonlinear Model Predictive Control (NMPC) problem with the objective of keeping the vision modules centered over the seed rows, and constraining the wheel motion to the defined Wheel tracks. The system and optimization problem has been implemented in Python using the Casadi framework. The implementation has been evaluated through simulations of the system, and compared with a PD controller. The NMPC approach display advantages and better performance when facing the path constraints of operating in row crops.

Authors

Marianne Stenrød Kirsten Tørresen Therese With Berge Andrea Ficke Ole Martin Eklo Anne K. Falk Øgaard Ola Flaten Karen Refsgaard Valborg KvakkestadAbstract

In Europe there is an on-going process on implementing regulations aimed at reducing pollution from agricultural production systems, i.e. the Water Framework Directive and the Framework Directive for Sustainable Use of Pesticides. At the same time, there is an increasing focus on food security possibly leading to continued intensification of agricultural production with increased use of external inputs, such as pesticides and fertilizers. Application of sustainable production systems can only be achieved if they balance conflicting environmental and economic effects. In Norway, cereal production is of large importance for food security and reduction of soil and phosphorus losses, as well as pesticide use and leaching/runoff in the cereal production are of special concern. Therefore, we need to determine the most sustainable and effective strategies to reduce loss of top soil, phosphorus and pesticides while maintaining cereal yields. A three-year research project, STRAPP, is addressing these concerns. A catchment area dominated by cereal production is our common research arena within STRAPP. Since 1992 a database (JOVA) with data for soil erosion, nutrient and pesticide leaching/runoff (i.e. concentrations in stream water), yield, and agricultural management practices (fertilization, use of pesticides, soil tillage and rotations) has been established for this catchment allowing us to compare a unique diversity in cropping strategies in a defined location. An important part of STRAPP focuses on developing ‘best plant protection strategies’ for cereal fields in the study area, based on field inventories (manual and sensor based) of weeds and common diseases, available forecast systems, and pesticide leaching risk maps. The results of field studies during the growing seasons of 2013 and 2014 will be presented, with a focus on possible integrated pest management (IPM) strategies for weeds and fungal diseases in cereal production. We will also present the project concept and methods for coupling optimized plant protection strategies to (i) modelling of phosphorus and pesticide leaching/runoff, as well as soil loss, and (ii) farm-economic impacts and adaptations. Further, methods for balancing the conflicting environmental and economic effects of the above practices, and the evaluation of instruments for increased adoption of desirable management practices will be outlined.

Authors

Trygve Utstumo Jarle Dørum Mathias Arbo Therese With Berge Steve Goldberg Øyvind Overskeid Tommy GravdahlAbstract

No abstract has been registered

Abstract

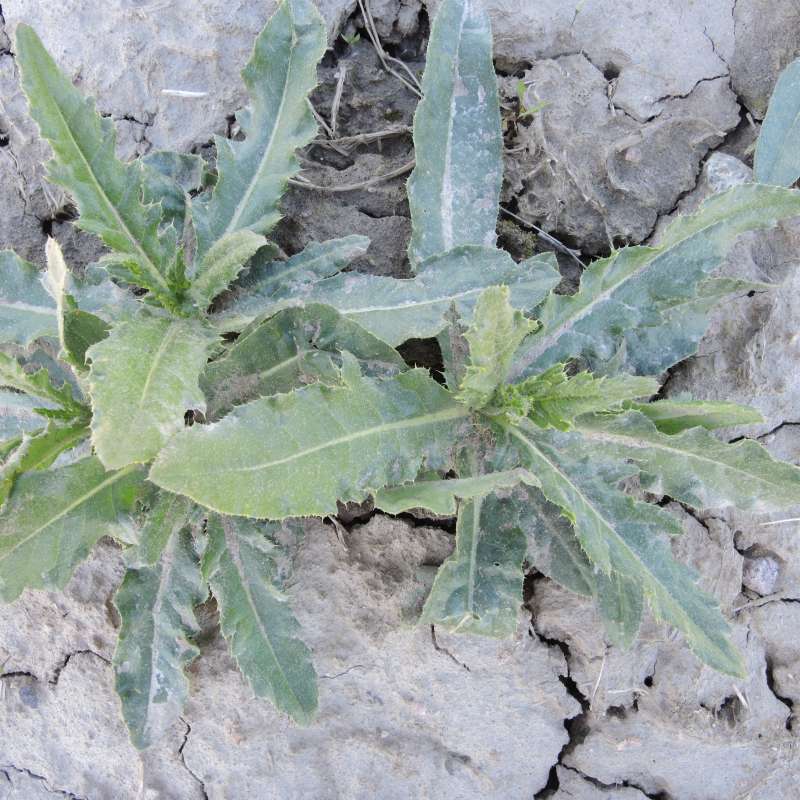

The purpose of our study is to explore the possibility to use proximate RGB imagery as basis for site-specific management of perennial weeds in small grain cereals. The targeted species are the broadleaved weeds Cirsium arvense (L.) Scop. (Creeping thistle) and Sonchus arvensis L. (Perennial sowthistle) and the grass weed Elymus repens (L.) Gould. (Common quackgrass). These are the main challenges for perennial weed control in cereals in Norway and temperate zone. The overall idea is to make weed maps based on images acquired during harvest in autumn (August/September) and use these maps for site-specific weed management when these species are normally managed in Norway, i.e. 3-4 weeks after harvest (E. repens) or in the following spring, i.e. late May/early June (C. arvense and S. arvensis). An on-the-go weed detection and glyphosate application in one operation before harvest is also a possible usage of our image-based method where this timing of glyphosate application is allowed. Images were acquired with a consumer grade camera mounted on a 3 m pole and tilted to mimic images acquired from the roof of a combine harvester. Images were acquired few days before harvest, a period where the cereals are yellowish and weed leaves and stalks are still green. Plots, 8 m by 8 m, were established in cereals to cover a wide range in weed pressure- and flora. The four plot corners were marked with white styrofoam balls mounted on sticks prior imaging and recorded with GPS (10 cm accuracy). The machine vision algorithm performs first a geometrical transform to represent the images as pseudo-orthonormal to the ground plane. This transform is aided by white styrofoam balls marking the corners of the plot with known distance. In the intended practical use, the transform can be done by obtaining the camera-angle and heading from inertial and GPS measurements and assuming level ground. The classification algorithm starts by segmenting the image into a class for green parts of the weeds (leaf, stalk), and three classes for flower heads (yellow, white and purple), by using threshold filters in the HSV colour space. A connected components analysis is then performed on each of the binary images, where the very small regions are filtered out. The area and centre of each region is calculated for comparison with ground truth observations. Two types of ground truth data for evaluation of the algorithm are available: Manual assessment of weed coverage from computer display of images and weed maps based on GPS measurements at the time for their management. Machine vision algorithm outputs versus ground truth data will be presented.

Abstract

Vehicles which operate in agricultural row crops, need to strictly follow the established wheel tracks. Errors in navigation where the robot sways of its path with one or more wheels may damage the crop plants. The specific focus of this paper is on an agricultural robot operation in row cultures. The robot performs machine vision detecting weeds within the crop rows and treats the weeds by high precision drop-on-demand application of herbicide. The navigation controller of the robot needs to follow the established wheel tracks and minimize the camera system offset from the seed row. The problem has been formulated as a Nonlinear Model Predictive Control (NMPC) problem with the objective of keeping the vision modules centered over the seed rows, and constraining the wheel motion to the defined Wheel tracks. The system and optimization problem has been implemented in Python using the Casadi framework. The implementation has been evaluated through simulations of the system, and compared with a PD controller. The NMPC approach display advantages and better performance when facing the path constraints of operating in row crops.

Abstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

JC. Streibig J. Rasmussen D. Andùjar C. Andreasen Therese With Berge D. Chachalis T. Dittmann Gerhard Gerhardsen T. M. Giselsson P. Hamouz C. Jaeger-Hansen K. Jensen R.N. Jørgensen M. Keller M. Laursen H.S Midtiby J. Nielsen S. Muller H. Nordmeyer G. Peteinatos A Papadopoulos J. Svensgaard M. Weis S. ChristensenAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Abstract

No abstract has been registered

Abstract

No abstract has been registered

Authors

Trygve Utstumo Jarle Dørum Mathias Arbo Therese With Berge Steve Goldberg Øyvind Overskeid Jan Tommy GravdahlAbstract

The Asterix project develops an autonomous robot for automatic weed control in row-crops. The system will only apply a fraction of the herbicide used in conventional application. The Food and Agriculture Organization of the United Nations estimate that the worlds food production needs to increase by 60 % by to feed the growing world population. This cannot be ful lled by conventional agricultural methods on the worlds available farm lands. Precision Agriculture (PA) is the concept of measuring eld variability and introducing this information as a feed-back to the crop management. PA can increase yields and optimize the resource inputs, and reduce environmental damages by avoiding excess use of herbicides, pesticides and fertilizers. The Asterix project is an ultra-precise weed control approach, where individual weed leaves are controlled by herbicide droplets. The droplets are dispensed by an 18 cm wide array of drop-on-demand nozzles (DoD).

Authors

JC. Streibig J. Rasmussen D. Andùjar Therese With Berge D. Chachalis T. Dittmann R. Gerhards TM: Giselsson P. Hamouz C. Jaeger-Hansen K. Jensen RN. Jørgensen M. Keller M. Laursen HS Midtiby J. Nielsen S. Muller H. Nordmeyer H. Peteinatos A. Papadopolous J. Svensgaard M. Weis S. ChristensenAbstract

No abstract has been registered

Authors

S. Christensen D. Andùjar Therese With Berge D. Chachalis T. Dittmann R. Gerhards TM. Giselsson P. Hamouz C. Jaeger-Hansen RN. Jørgensen M. Keller M. Laursen HS. Midtiby J. Nielsen S. Müller Hamouz Nordmeyer G. Peteinatos A. Papadopolous J. Rasmussen J. Svensgaard M Weis JC. StreibigAbstract

No abstract has been registered

Abstract

Arable weeds are generally distributed in patches, while herbicides are applied uniformly. Herbicides can be saved if only the patches are sprayed, i.e. patch spraying (PS). Bottlenecks for cost-effective PS are weed monitoring technology and valid technology-based decision rules for PS (thresholds). The novel machine vision algorithm Weedcer has been developed as an efficient weed monitoring tool for PS. Weedcer estimates the proportions of young weed leaves and cereal leaves in high resolution red–green–blue images. We conducted field trials to test relative weed cover (RWC) and relative mayweed cover (RMC) estimated by Weedcer as decision rules for PS. RWC is the total weed cover divided by the total plant cover and RMC is the mayweed cover divided by the total plant cover. The main criterion for evaluation and basis of these thresholds was the measured grain yield. Images (about 0.06-m2) were acquired with a GPS guided autonomous field robot in spring, the normal time for spraying seed-propagated broadleaf weeds in both winter – and spring cereals in Norway. Three map-based trials (weed monitoring and spraying in two separate operations) showed that mean RWC per management unit (12.0 × 12.5-m) was generally adequate. In winter wheat heavily infested with scentless mayweed (Tripleurospermum inodorum (L.) Sch.Bip.) and/or scented mayweed (Matricaria recutita L.), the mean RMC per management unit was more adequate. Progress during the project allowed three additional trials conducted in real-time (weed monitoring and spraying in the same operation). These were conducted with the robot in spring cereals, and showed that a weighted moving average of RWC per image was adequate. The sprayed and unsprayed management units in these trials were minimum 3.0 × 3.0-m and 0.5 × 3.0-m, respectively. Results indicated that the Weedcer-based thresholds should be lower in wheat (Triticum aestivum) than in barley (Hordeum vulgare).

Authors

Therese With BergeAbstract

No abstract has been registered

Abstract

No abstract has been registered

Authors

Jan Netland Kari AarekolAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Abstract

No abstract has been registered

Authors

Therese With Berge Steve Goldberg Daniel Løvås Jan Netland Øyvind OverskeidAbstract

I samarbeid med Adigo AS har Bioforsk Plantehelse påbegynt utvikling av en ugrasrobot som skal kontrollere ugras i radene av kålrot.

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Jan Netland Therese With Berge Steve Goldberg Publikasjonsforfatter Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Kristin Kaspersen Therese With Berge Steve Goldberg Jan Netland Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Steve Goldberg Kristin Kaspersen Steve Goldberg Jan Netland Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Therese With Berge Steve Goldberg Daniel Løvås Jan Netland Øyvind OverskeidAbstract

No abstract has been registered

Authors

Therese With Berge Steve Goldberg Daniel Løvås Jan Netland Øyvind OverskeidAbstract

No abstract has been registered

Authors

Therese With Berge Jan Netland Steve Goldberg Kristin Kaspersen Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Therese With Berge Steve Goldberg Kristin Kaspersen Jan Netland Publikasjonsforfatter Trygve StølanAbstract

No abstract has been registered

Authors

Therese With Berge Steve Goldberg Kristin Kaspersen Jan Netland Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Steve Goldberg Kristin Kaspersen Jan Netland Øyvind Overskeid Trygve StølanAbstract

No abstract has been registered

Authors

Therese With BergeAbstract

Utvikling av skadeterskler basert på nyutviklet bildeanalyseprogram for presisjonssprøyting (flekksprøyting; sprøyting etter behov; stedsspesifikk sprøyting) mot frøugras i korn

Authors

Therese With Berge Jan Netland Marit Helgheim Kjell Wærnhus Asbjørn Berge Sigmund Clausen Kristin Kaspersen Steve Goldberg Øyvind Overskeid Trygve Stølan Trygve StølanAbstract

Ugras vokser ofte flekkvis og sprøyting gir ikke meravling i alle deler av kornåkeren. Derfor er sprøyting etter behov, eller flekksprøyting, en god løsning. For å praktisere flekksprøyting er kamerabasert styring av åkersprøyta nødvendig. Foredraget gir innblikk i et KMB prosjekt som utvikler kamerabaserte skadeterskler for flekksprøyting av frøugras i korn.

Abstract

Lack of automatic weed detection tools has hampered the adoption of site-specific weed control in cereals. An initial object-oriented algorithm for the automatic detection of broad-leaved weeds in cereals developed by SINTEF ICT (Oslo, Norway) was evaluated. The algorithm ("WeedFinder") estimates total density and cover of broad-leaved weed seedlings in cereal fields from near-ground red-green-blue images. The ability of "WeedFinder" to predict 'spray'/'no spray' decisions according to a previously suggested spray decision model for spring cereals was tested with images from two wheat fields sown with the normal row spacing of the region, 0.125 m. Applying the decision model as a simple look-up table, "WeedFinder" gave correct spray decisions in 65-85% of the test images. With discriminant analysis, corresponding mean rates were 84-90%. Future versions of "WeedFinder" must be more accurate and accommodate weed species recognition.

Abstract

A possible cost-effective real-time patch spraying implementation against seed-propagated broad-leaved weeds in cereals is a camera mounted in front of the tractor taking images at feasible distances in the direction of travel, on-board image analysis software and entire boom switched on and off. To assess this implementation, manual weed counts (0.25 m(2) quadrats) in a 1.5 m x 2 m grid, were used to simulate camera outputs. Each quadrat was classified into 'spray' and 'not spray' decisions based on a threshold model, and the resulting map defined the 'ground truth'. Subsequently, 'on/off' spraying at larger control areas where sizes were given by the boom width and image distance, and spraying decision controlled by weed status at the single quadrat simulating the camera's view, were simulated. These coarser maps were compared with 'ground truth', to estimate mapping error (area above threshold not sprayed), spraying error (area below threshold sprayed), total error (sum of mapping and spraying error) and the herbicide reduction. Three levels of the threshold model were tested. Results were used to fit models that predict errors from boom width and image distance. Size of control area did not on average affect the magnitude of the simulated herbicide reductions, but the bigger the control area the higher the risk that the simulated herbicide reduction deviate from the reduction in 'ground truth'. Mean simulated herbicide reductions were 42-59%, depending on threshold level. Only minor differences due to threshold level were seen for mean mapping and spraying errors at given spraying resolutions. Using original threshold level and image distance 2 m, predicted total errors for boom widths 2 m, 6 m, 20 m and 40 m would be 6%, 10%, 16% and 17%, respectively. Results indicate that control area should not exceed about 10 m 2 if acceptable total error is maximum 10%.

Authors

Therese With BergeAbstract

No abstract has been registered

Authors

Therese With Berge Haldor Fykse Are H. AastveitAbstract

A major obstacle to patch spraying of broad-leaved weeds in cereals is a cost-effective method to assess within-field heterogeneity of the weed population. One method could be a camera mounted in front of the spraying vehicle, online image analysis, and field sprayer shifting between "on" and "off" as the predefined weed damage threshold level is reached. Because such a camera will capture a very limited area (

Authors

Therese With Berge Are H. Aastveit Haldor FykseAbstract

En bildealgoritme ("WeedFinder") som automatisk estimerer ugrasmengde i digitale fargebilder ble evaluert.

Authors

Therese With Berge Henrik R. Cederkvist Are H. Aastveit Haldor FykseAbstract

Varying size of the management unit (MU, to be sprayed or not) were simulated for an envisaged implementation of image-based patch spraying based on mapped weed data. The simulations showed that the size of the MU had a great influence on the mapping errors (area above weed damage threshold, but unspared by big MU) and the spraying errors (area below threshold, but sprayed by the bigger MUs). If MU size is 10 m2, these errors would sum up to about 10%.

Authors

Therese With Berge Jan NetlandAbstract

Status i Norge og internasjonalt presenteres.

Authors

Therese With Berge Haldor FykseAbstract

Generelt er ugras hverken homogent eller tilfeldig fordelt i en åker, men klumpvis på en eller annen skale. Dette bør utnyttes til presisjonssprøyting (PS). En viktig hindring for gjennomføring av presisjonssprøyting mot frøugras i korn i dag er at gårdbrukeren ikke vet om ugrasmengden i området han kjører i, er over eller under skadeterskelen. En relativt enkel løsning er å montere et digital-kamera foran på traktoren, koble dette til PC med hurtige bildeanalyse-algoritmer og skadeterskler, og la PC"n styre åkersprøyta på/av automatisk. Ettersom dette kameraet vil fange opp et svært begrenset areal i forhold til hele sprøytebomsbredden, undersøkte vi hvor representativ informasjonen fra én telleramme på 0,25 m2 (simulert sprøytebredde). Tjue kornfelt a 192 tellerammer i 2001 og 2002 lagt i de viktigste korndistriktene i Norge ble analysert. Vi estimerte også hvor store areal som ikke ville blitt sprøyta ved PS, og dermed hvor mye herbicid korndyrkeren (og samfunnet) kunne spart med PS. Studien konkluderer med at én observasjon per bombredde, altså ett kamera, virker fornuftig, og at ca. 60 % av undersøkt kornareal var under skadeterskelen, og dermed unødvendig å sprøyte.

Authors

Therese With Berge Haldor FykseAbstract

Site-specific weed management (SSWM) of annuals will probably only be adopted by Norwegian cereal farmers if a cheap SSWM design becomes available. This could be one camera mounted in front of tractor taking images along a narrow path at the middle of sprayer boom, and nozzles automatically and collectively switched on as economic damage threshold is reached. We tested the suitability of this design ("SSWM, Low") by comparing spraying decisions ("spray"/"not spray") of this low resolution (about 16-m) with a high resolution (about 2-m) design ("SSWM, High"). Study concluded that one camera per spray boom (about 16-m wide) seems suitable because mean spraying error, as compared to "SSWM, High", was only 10%. Mean herbicide reductions were c. 60% for both SSWM designs.

Projects

Division of Biotechnology and Plant Health

SOLUTIONS: New solutions for potato canopy desiccation, control of weeds and runners in field strawberries & weed control in apple orchards

Efficient measures for weed control and similar challenges are vital to avoid crop loss in agriculture. National supply of food, feed and other agricultural products depends on each farmer’s success managing their fields and orchards. The recent loss of the herbicide diquat, and the potential ban on glyphosate, - both important tools for farmers -, raise a demand for new measures for vegetation control. Efficient alternatives to herbicides are also important tools in Integrated Pest Management (IPM). Norwegian growers need to document compliance to IPM since 2015 to ensure minimum hazards to health and environment from pesticide use.

Division of Biotechnology and Plant Health

AC/DC-weeds: Applying and Combining Disturbance and Competition for an agro-ecological management of creeping perennial weeds

Målsetningen med prosjektet AC/DC-weeds er å utvikle metoder for bærekraftig kontroll av flerårig vandrende ugras (rotugras) som kveke, åkerdylle og åkertistel i landbruket. Målet er å redusere behovet for intensiv jordarbeiding som pløying og å finne alternativer til bruk av ugrasmiddelet glyfosat. Nye metoder for bærekraftig kontroll av rotugras krever at en kombinerer flere typer av både forebyggende og direkte bekjempingstiltak. Kunnskap fra prosjektet vil formidles til viktige målgrupper som rådgivere, bønder og andre relevante mottakere. Rostock Universitet (Tyskland) ved Prof. Dr. Bärbel Gerowitt er prosjektkoordinator. NMBU ved Prof. Dr. Lars Olav Brandsæter administrerer aktiviteten i Norge.

Division of Biotechnology and Plant Health

PresiHøstkorn: Redusert forbruk av ugrasmidler i korn - skadeterskler for presisjonssprøyting i høstkorn

Ugras er svært ofte flekkvis fordelt i åkeren. Korn er en konkurransesterk kultur og tåler en god del frøugras før det får negative konsekvenser. Det vil si at det eksisterer skadeterskler som angir hvor i åkeren ugrastiltak er nødvendig. Presisjonssprøyting (automatisk sensor-basert flekksprøyting) er å ta hensyn til den flekkvise utbredelsen av ugraset i åkeren. Dette vil redusere forbruket av ugrasmiddel betydelig i forhold til vanlig praksis (breisprøyting). På sikt forventes presisjonssprøyting å redusere forbruket av frøugrasmiddel med minst 50 %.

Division of Food Production and Society

PRESIS

I PRESIS, et nytt femårig samarbeidsprosjekt, skal NIBIO være med å videreutvikle teknologiske løsninger for enda bedre presisjonsjordbruk, og samtidig sørge for at løsningene kommer ut i praksis til gårdene.

Division of Biotechnology and Plant Health

SMARTCROP

I prosjektet vil vi teste og demonstrere «beste IPV-praksis» og studere effekter på skadegjørere, naturlige fiender, avling, økonomi og miljørisiko i to ettårige- (korn) og to flerårige modellvekster (eple og jordbær). Arbeidet er delt inn i fire faglige arbeidspakker (AP), se egne omtaler av disse i menyen til venstre.

Division of Biotechnology and Plant Health

VEGINN: Innovasjon for bedre ugresskontroll i grønnsaker

Division of Biotechnology and Plant Health

Innovationer för hållbar växtodling

Division of Biotechnology and Plant Health

Test av kommersiell teknologi for presisjonssprøyting av glyfosat i korndproduksjon

Multisensory precision agriculture – improving yields and reducing environmental impact

FORURENS - Strategies for implementation of sound cereal production methods with low loss of pesticides and phosphorus (STRAPP)

National cereal production is of large importance for food security. Cereal crops cover 30% of the farmland, and most of the cereal area is sprayed annually.