Giovanna Ottaviani Aalmo

Research Scientist

(+47) 980 30 422

giovanna.ottaviani.aalmo@nibio.no

Place

Ås O43

Visiting address

Oluf Thesens vei 43, 1433 Ås

Authors

Rosaria Arena Giuseppe Renda Giovanna Ottaviani Aalmo Frédéric Debeaufort Concetta Maria Messina Andrea SantulliAbstract

No abstract has been registered

Authors

Monica Ubalde-Lopez Mark Nieuwenhuijsen Giuseppina Spano Giovanni Sanesi Carlo Calfapietra Alice Meyer-Grandbastien Liz O’Brien Giovanna Ottaviani Aalmo Fabio Salbitano Jerylee Wilkes-Allemann Payam DadvandAbstract

No abstract has been registered

Abstract

No abstract has been registered

Division of Food Production and Society

ENFASYS - ENcouraging Farmers towards sustainable farming SYstems through policy and business Strategies

Today’s farmers find it difficult to deal with the several lock-ins within food systems that keep them from transitioning to sustainable farming systems. Policies, together with business models and social innovations, need to be strengthened to overcome lock-in challenges

Division of Environment and Natural Resources

CANALLS Agroecological practices for sustainable transition

Agroecology covers all activities and actors involved in food systems. It also places the well-being of people (producers and consumers of crops and products) at its core. The EU-funded CANALLS project will focus on the agroecological zones and diverse farming systems in the humid tropics of Central and Eastern Africa. It will explore the complex environmental, social and economic challenges, which in some cases are exacerbated by conflict and high vulnerability. Moreover, it will advance agroecological transitions in these regions through multi-actor transdisciplinary agroecology Living Labs at eight sites in four countries. The focus will be on crops such as cocoa, coffee and cassava, which are vital for subsistence and economic development.

Division of Food Production and Society

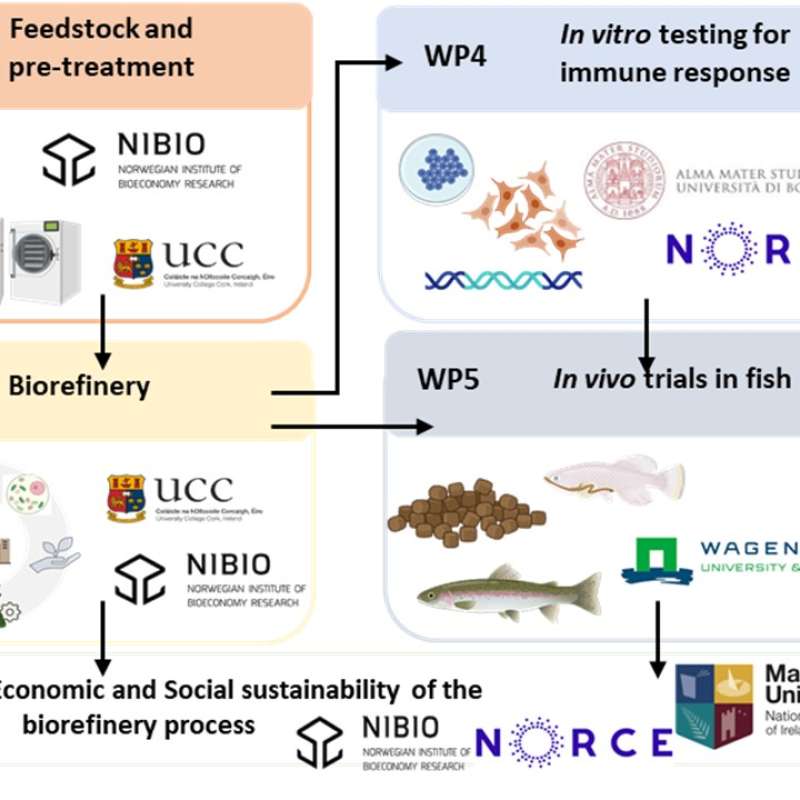

AquaUP - Aquafeed Upgraded: Enhancing Immune Function of Fish with Seaweed-modified Functional Compounds

The aquaculture industry is anticipating intensive production growth to meet future food demand. Yet, this growth is constrained by a number of challenges, not least including disease spread and use of antibiotics and chemicals to combat or reduce disease outbreaks.