Fish could become a by-product of future aquaculture

Initial feeding of spotted wolffish. Photo: Jonny Nikolaisen

Zero emissions, improved fish health and new value chains based on sludge. A new research collaboration between NIBIO and Multigen Akva could pave the way for a more circular aquaculture industry. “In the long term, the fish itself could become a by-product,” says senior adviser Gjermund Bahr at NIBIO.

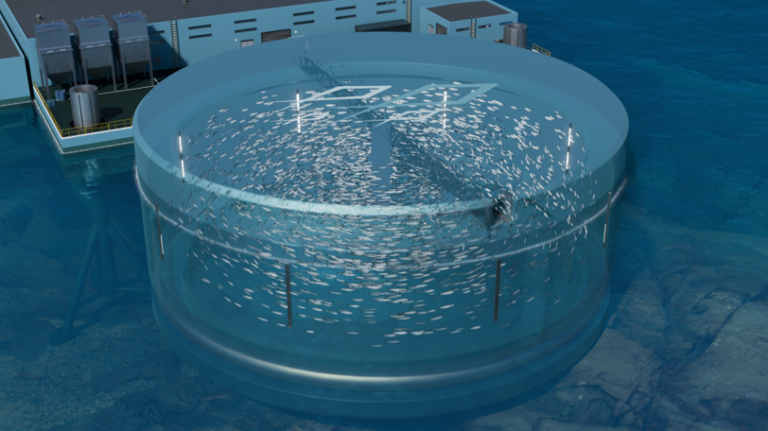

The Norwegian Institute of Bioeconomy Research (NIBIO) and Multigen Akva AS have joined forces in an extensive research and development initiative and are applying for an R&D licence to farm salmon in a closed, sea-based RAS system (Recirculating Aquaculture System). The goal is to establish a new standard for circular resource use in aquaculture—where waste is transformed into valuable products.

The project combines Multigen Akva’s floating RAS platform with NIBIO’s expertise in aquaculture, agriculture, biogas, biorefining and circular systems. The ambition is to document how clean sludge fractions from aquaculture can be upgraded into high-value products such as proteins and omega-3, using a closed offshore system with zero emissions.

“We want to move from linear to circular production and demonstrate that zero-emission aquaculture is not only possible, but can also become a competitive advantage,” says Kristoffer Høyning, CEO of Multigen Akva.

Addressing aquaculture’s greatest challenges

Today’s aquaculture industry faces major challenges related to fish health, environmental impact and resource efficiency.

“Aquaculture has largely been a linear industry. Much of the waste remains in the sea, and mortality rates are too high. Nationwide, around 1.5 million tonnes of fish are produced annually in open cages. Of these, 16–17 percent die. That is a clear signal that change is needed,” says Høyning.

He also points out that the advantages of open-net pen farming are gradually diminishing.

“Climate change, increased disease pressure and declining water quality will place ever greater stress on the fish. At the same time, far too little of the sludge is managed as a resource,” he says.

New technology for a global market

Multigen Akva’s technology is based on a closed RAS 2 system at sea, where all incoming and outgoing water is filtered down to virus level. All process water is treated, and all sludge is collected for further upgrading.

“In this system, the fish are protected from sea lice, diseases, algae and other external stressors. The water is recirculated, cleaned and reused, and the sludge goes from being a waste problem to a potential source of revenue,” says Bahr.

The platforms use only around three percent of the area required by traditional facilities, can be located close to shore and require relatively little energy. They also do not depend on large moorings like open cages do and can be deployed in water depths ranging from seven to 40 metres. The RAS platforms are also designed to eliminate issues related to internal waves.

“Developing this technology could position Norway as a leading supplier of new aquaculture technology worldwide. That is why we say that, in the long term, the fish itself could become a by-product,” Bahr explains.

Standardised sludge: the key to new circular value chains

One of the most promising aspects of the project is the possibility of producing sludge that can be standardised and certified within a fully closed system. Full control of input factors and environmental conditions ensures that problematic substances are prevented from entering the system.

“Such a solution provides optimal conditions for the fish. At the same time, the sludge produced is unique. When all water entering and leaving the system is filtered through membranes, and the fish sludge is not exposed to net coatings, microplastics, pharmaceutical residues or unknown heavy metals, what remains is a resource influenced only by the feed and the fish’s natural biology,” Bahr continues.

The Multigen system collects sludge from the entire production chain—from tanks with mechanical filters, biofilters, denitrification and phosphorus precipitation. These fractions yield several distinct, clean and well-defined sludge components that can be utilised individually or combined into new products.

A living research laboratory

The closed facility also functions as a fully controllable research laboratory.

“When we can control all input factors—such as water, temperature, light, oxygen, CO₂, microbiology and nutrients—we gain a research arena that simply does not exist in open sea systems,” says Bahr.

This opens up new opportunities for research on fish welfare, feeding strategies, microbiology and nutrient flows—knowledge that can help develop new circular value chains linking aquaculture and agriculture.

Strengthening Norway’s international position

Through the R&D licence, NIBIO and Multigen aim to investigate how clean sludge fractions from aquaculture can be integrated into high-value value chains to produce, among other things, proteins and omega-3.

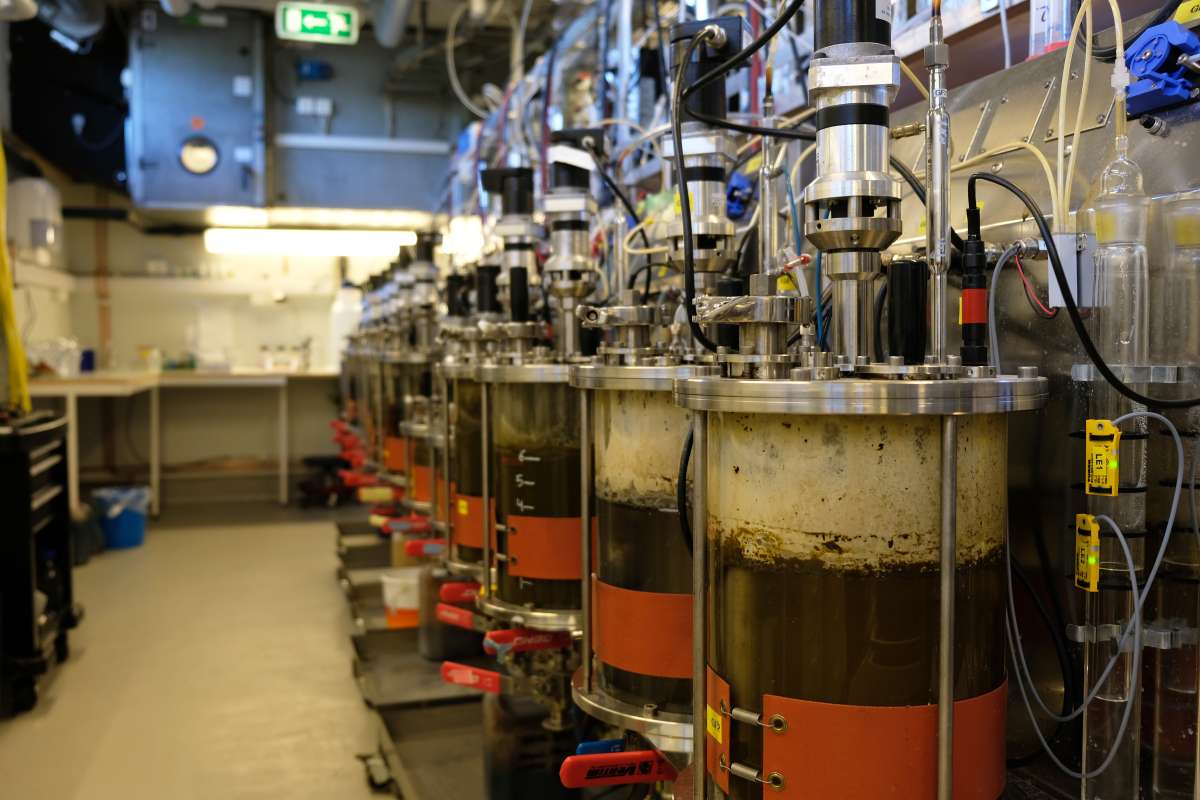

“This could generate new knowledge that is relevant to both aquaculture and agriculture and strengthen Norway’s position in climate-friendly and circular food production. NIBIO already has infrastructure for biorefining, including facilities at the experimental station at NIBIO Tuv, Steinkjer,” says Bahr.

Høyning shares this optimism.

“Imagine if we could produce salmon with zero emissions, improve fish welfare and at the same time create value from what is currently regarded as waste. That is what truly sustainable solutions look like. The potential for Norwegian aquaculture is enormous,” he concludes.

Contacts

Gjermund Bahr

Senior Adviser

-

Division of Food Production and Society

(+47) 915 59 281 gjermund.bahr@nibio.no Office Location: Steinkjer

Links

Multigen Akva ASAquaculture sludge can become a resource

In Norway, aquaculture facilities may produce around 500,000 tonnes of dry sludge annually.

This sludge can be used as a substrate for algae production, together with by-products from agriculture.

Marine microalgae are the original producers of omega-3 in the ocean. When they are cultivated with sludge and other residual products in a biorefinery, it enables sustainable production of high-quality omega-3 fatty acids within a circular system linking agriculture, industry, and aquaculture.

There is significant potential in expanding the species diversity of microalgae.

Contacts

Gjermund Bahr

Senior Adviser

-

Division of Food Production and Society

(+47) 915 59 281 gjermund.bahr@nibio.no Office Location: Steinkjer