Division of Forest and Forest Resources

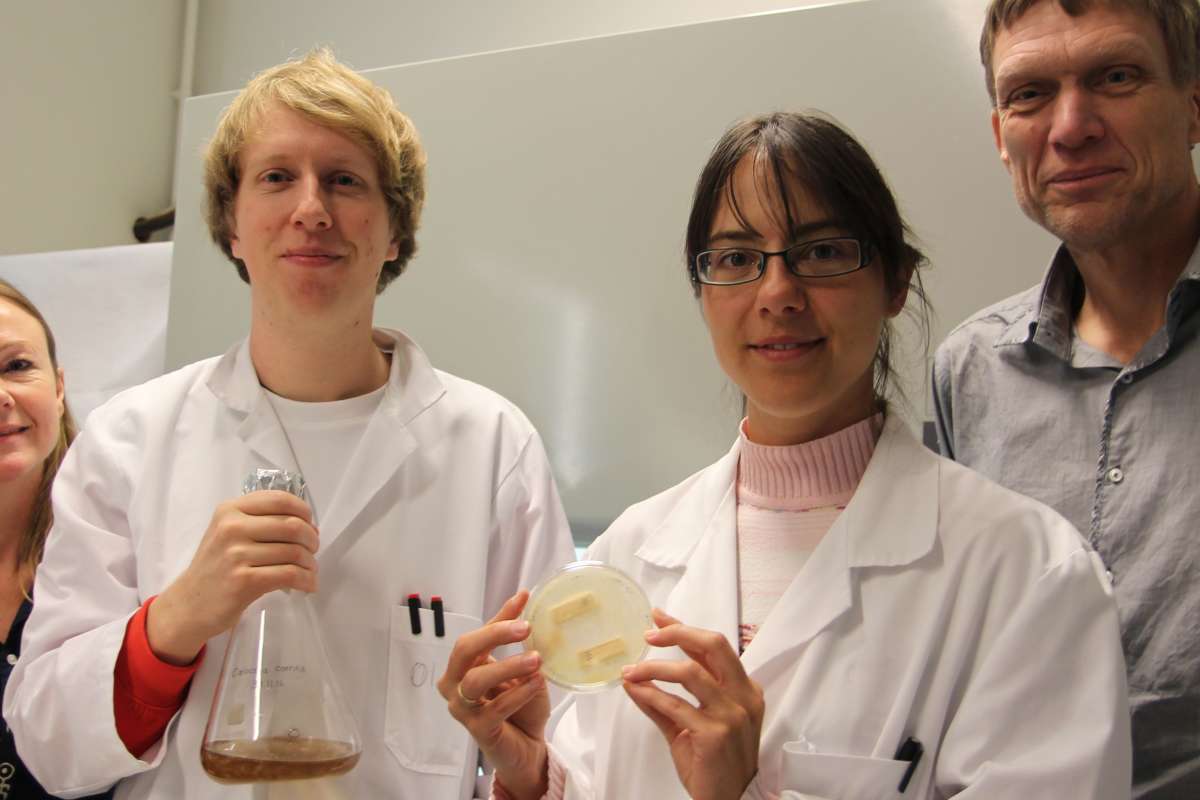

BioMim - Advancing biomass technology

End: dec 2018

Start: jan 2015

| Start - end date | 01.01.2015 - 30.12.2018 |

| Project manager | Gry Alfredsen |

| Division | Division of Forest and Forest Resources |

| Department | Wood Technology |

| Partners | Norwegian University of Life Sciences, University of Oslo, Paper and Fibre Research Institute, Borregaard, Kebony, Virginia Polytechnic Institute and State University (Virginia Tech), University of Tennessee, SP Technical Research Institute of Sweden, University of Copenhagen, Tokyo University of Agriculture and Technology |

| Total budget | 27,3 mill NOK |

| Budget this year | 2 mill NOK |

| Funding source | The Research Council of Norway |

Summary

We want to learn from nature how to do more with Scandinavian wood resources. The two primary wood species in Norway are Norway spruce (47%) and Scots pine (33%). Brown rot fungi occur primarily on conifer wood and in the boreal forest. Early in the brown rot decay process, extensive depolymerization of the wood cell wall occurs, causing the wood to rapidly lose strength in comparison to the rate of wood metabolism. This causes challenges for wood in service but creates possibilities for developing technologies for biorefining.

Enzymes, which are a key tool for biomass depolymerization, cannot penetrate the intact wood cell walls. Brown-rot fungi possess unique mechanisms employing the use of small metabolites such as iron ions to selectively remove biomass components, thus creating much improved access to their enzymes. This mechanism can be exploited in biorefining, while on the other hand, it needs to be controlled to prevent fungal damage to wood in service.

Exploitation of this kind of chemistry in (industrial) biomass conversion has so far been of limited success, due to a lack of understanding of the reaction process and of the interplay between various enzyme types, metabolites and reaction conditions. Through the BioMim project, we will acquire new insights into how brown rot fungi degrade wood and these will be used to improve biorefining processes as well as wood protection.

Work Packages

Extensive exploitation of lignocellulosic biomass as a feedstock for a variety of products is the key to develop a viable bio-economy. However, the natural resistance of lignocellulosic biomass to chemical and biological deconstruction is a challenge that biorefineries have to overcome.

- Peer review papers

- Scientific conferences

- The use of social media and networks to create dialogue with target groups

- The project will organise work shops and seminars

Publications in the project

Authors

Olav Aaseth Hegnar Gry Alfredsen Vincent Eijsink Carl Gunnar Fossdal Barry Goodell Aniko VarnaiAbstract

No abstract has been registered